Epoxy coatings have become a popular choice for protecting and enhancing wood surfaces, thanks to their durability, seamless finish, and resistance to moisture and chemicals. However, as with any DIY project, several potential pitfalls can occur if the application process is not executed correctly. In this comprehensive guide, we’ll explore what can go wrong when epoxy coating over wood and how to prevent these issues for a flawless finish.

Common Epoxy Coating Issues

Fisheyes and Craters

Fisheyes and craters are small, crater-like imperfections that can appear on the surface of the epoxy coating. These defects are often caused by contamination or improper surface preparation, which prevents the epoxy from adhering correctly.

Cloudy or Hazy Finish

A cloudy or hazy appearance in the epoxy coating can result from various factors, including improper mixing, insufficient hardener, or exposure to moisture during the curing process.

Soft or Sticky Areas

If the epoxy coating remains soft or sticky after the recommended curing time, it could be due to incorrect mixing ratios, insufficient hardener, or improper application techniques.

Peeling or Delamination

Peeling or delamination occurs when the epoxy coating separates from the wood surface. This issue is typically caused by inadequate surface preparation, contamination, or incompatibility between the epoxy and the wood substrate.

Preventing Epoxy Coating Issues

Surface Preparation

Proper surface preparation is crucial for a successful epoxy coating application. Follow these steps:

- Clean the wood surface thoroughly, removing any dirt, grease, or contaminants.

- Sand the surface to create a roughened texture for better adhesion.

- Remove all dust and debris from the sanding process.

Mixing and Application

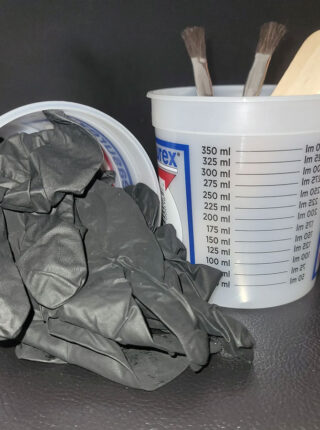

Carefully follow the manufacturer’s instructions for mixing and applying the epoxy coating:

- Mix the epoxy resin and hardener in the correct ratios, using a clean container and mixing stick.

- Ensure thorough mixing to avoid incomplete curing or soft spots.

- Apply the epoxy coating in thin, even layers, following the recommended coverage rates and application techniques.

Environmental Conditions

Pay close attention to the environmental conditions during application and curing:

- Maintain the recommended temperature range for proper curing.

- Ensure adequate ventilation to prevent moisture buildup or contamination.

- Avoid drafts or excessive air movement, which can introduce dust or debris.

FAQs about Epoxy Coating Over Wood

Can I apply epoxy over stained or painted wood?

While it is possible to apply epoxy over stained or painted wood, proper surface preparation is crucial. The existing finish must be thoroughly deglossed or sanded to ensure proper adhesion.

How long does epoxy take to cure?

Curing times can vary depending on the specific epoxy product and environmental conditions. Typically, epoxy coatings can take anywhere from 24 to 72 hours to fully cure.

Can I recoat or touch up an existing epoxy coating?

Yes, it is possible to recoat or touch up an existing epoxy coating, but the surface must be properly prepared by sanding and cleaning to ensure proper adhesion.

Is epoxy coating over wood food-safe?

Not all epoxy coatings are food-safe. If you plan to use the coated surface for food preparation or consumption, ensure you choose a specifically formulated food-safe epoxy coating.

Top Tips for Successful Epoxy Coating Over Wood:

- Thoroughly clean and prepare the wood surface for optimal adhesion.

- Follow the manufacturer’s mixing and application instructions precisely.

- Maintain the recommended temperature and ventilation conditions during application and curing.

- Apply the epoxy coating in thin, even layers for a smooth, consistent finish.

- Allow sufficient curing time before subjecting the surface to heavy use or wear.

About the Author

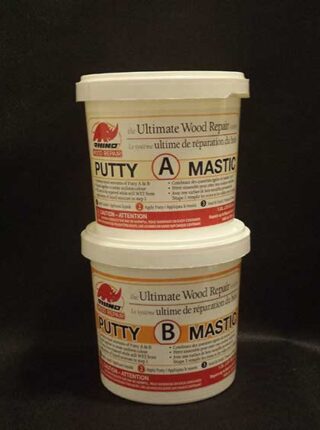

This comprehensive guide on potential issues with epoxy coating over wood was brought to you by Rhino Wood Repair, a company dedicated to providing top-quality wood repair solutions. Our founder and chemist, Robin Pixner, has years of experience in the industry and a passion for helping homeowners and professionals alike achieve flawless woodwork.

At Rhino Wood Repair, we understand the importance of preserving the beauty and longevity of wood surfaces. Our products are carefully formulated to ensure exceptional results, whether you’re tackling a small DIY project or a large-scale restoration.

With our expertise and commitment to excellence, you can trust Rhino Wood Repair to provide you with the knowledge and tools you need to tackle any wood repair project with confidence. Visit our website or contact us today to learn more about our innovative wood repair solutions. See our wood repair products here.

Frequently Asked Questions

Frequently Asked Questions Videos

Videos Colourful Chemist cooks up wood-repair product

Colourful Chemist cooks up wood-repair product Custom Adhesive Epoxies & Formulations

Custom Adhesive Epoxies & Formulations THE SIMPLE SOLUTION TO A DIFFICULT PROBLEM.

THE SIMPLE SOLUTION TO A DIFFICULT PROBLEM.

Rhino Wood Repair for Log Homes Looking to combat wood rot on your log home? Enter Rhino Wood Repair — the vanguard of wood restoration, with a legacy spanning over three decades. Led by Robin Pixner, a visionary in the field of wood preservation, our mission is simple yet profound: to breathe new life into aging wood, to fortify its strength, and to ensure that the legacy of log homes endures for generations to come.

Rhino Wood Repair for Log Homes Looking to combat wood rot on your log home? Enter Rhino Wood Repair — the vanguard of wood restoration, with a legacy spanning over three decades. Led by Robin Pixner, a visionary in the field of wood preservation, our mission is simple yet profound: to breathe new life into aging wood, to fortify its strength, and to ensure that the legacy of log homes endures for generations to come. Wood Epoxy

Wood Epoxy