Description

![]() Technical Data Sheet Putty A & B

Technical Data Sheet Putty A & B

in PDF format click here

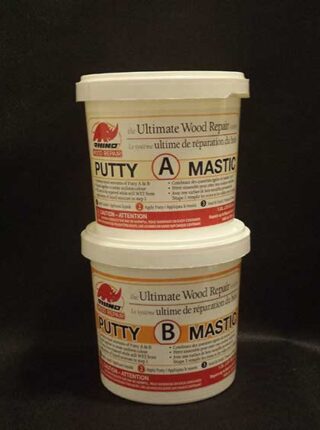

Our structural putty A and putty B system is 100% solids containing no solvents or no VOCs having a room temperature cure, slow gel time epoxy to be used in conjunction with our liquid A and B system.

Properties

Structural: Provides a permanent structural repair to wood.

Other Properties: Easy to shape, sculpt, sand, paint, stain, nail, screw for a permanent water-proof repair.

Protective: Provides a protective water-proof repair preventing further rot and repair to any exposed wood.

Typical uncured properties

Gel time (ASTM D-2471)

Coverage

One (1) kg covers approximately 4 to 5 m2 (43 to 54 ft2).

Typical cured properties

Minimum cure schedule for 16 hours @ 25°C

Pretreatment of surfaces

Surfaces being repaired must be dry, clean and sound. Use sandblasting, needle scalers, a powered grinding tool or scrapers to remove all traces of dirt, oil, curing compound, mold release agent and disintegrated materials.

Mixing

- Mix putty A only with putty B.

- Do not use damaged or leaking containers.

- Premeasure putty A and putty B separately. Then place the hardener into the resin container according to the required 100:100 mixing ratio.

- Knead putty A and putty B thoroughly until a uniform yellow colour. Continue to knead for an additional 30-45 seconds.

- Never dilute with solvents.

Cleaning of tools

Tools and equipment should be cleaned immediately after use vinegar or Lysol.

Storage

Keep containers closed until just before use at a temperature above 15°C.

Caution

Keep putty A and putty B away from eyes and skin. Like any reactive material, uncured putty A and putty

B may irritate sensitive skin. Wear protective clothing, goggles and gloves.

FIRST AID

Eyes

Flush immediately with plenty of water for 15 minutes and obtain medical aid.

Skin

Clean skin with warm water and a soft soap. Never use solvents to remove material from skin

Frequently Asked Questions

Frequently Asked Questions Videos

Videos Colourful Chemist cooks up wood-repair product

Colourful Chemist cooks up wood-repair product Custom Adhesive Epoxies & Formulations

Custom Adhesive Epoxies & Formulations THE SIMPLE SOLUTION TO A DIFFICULT PROBLEM.

THE SIMPLE SOLUTION TO A DIFFICULT PROBLEM.

Rhino Wood Repair for Log Homes Looking to combat wood rot on your log home? Enter Rhino Wood Repair — the vanguard of wood restoration, with a legacy spanning over three decades. Led by Robin Pixner, a visionary in the field of wood preservation, our mission is simple yet profound: to breathe new life into aging wood, to fortify its strength, and to ensure that the legacy of log homes endures for generations to come.

Rhino Wood Repair for Log Homes Looking to combat wood rot on your log home? Enter Rhino Wood Repair — the vanguard of wood restoration, with a legacy spanning over three decades. Led by Robin Pixner, a visionary in the field of wood preservation, our mission is simple yet profound: to breathe new life into aging wood, to fortify its strength, and to ensure that the legacy of log homes endures for generations to come. Wood Epoxy

Wood Epoxy