by Robin Pixner | Jun 28, 2024 | News

Water damage can be a homeowner’s worst nightmare, especially when it comes to beautiful wood floors. Whether it’s from a leaky pipe, a spill, or a natural disaster, water can wreak havoc on your hardwood flooring. But don’t despair! With the right knowledge and tools, you can restore your water-damaged wood floors to their former glory. In this comprehensive guide, we’ll walk you through the steps to assess, repair, and prevent future water damage to your cherished wood floors.

Understanding Water Damage in Wood Floors

Before we dive into the repair process, it’s crucial to understand how water affects wood flooring.

Types of Water Damage

- Surface damage: Caused by spills or minor leaks

- Deep damage: Results from prolonged exposure or flooding

- Structural damage: Affects the subfloor and floor joists

Signs of Water-Damaged Wood Floors

- Cupping: Edges of boards are higher than the center

- Crowning: Center of boards are higher than the edges

- Buckling: Boards completely detach from the subfloor

- Discoloration: Dark spots or stains on the wood

- Mold growth: Fuzzy or slimy patches on the surface

Steps to Fix Water-Damaged Wood Floors

- Assess the Damage

Before starting any repairs, carefully evaluate the extent of the damage:

- Identify the water source and stop it

- Determine if the damage is surface-level or deep

- Check for mold growth

- Assess the affected area’s size

- Remove Excess Water

Quick action is crucial to minimize damage:

- Use towels or a wet vacuum to absorb standing water

- Run dehumidifiers and fans to dry the area

- Open windows for better air circulation

- Clean and Disinfect

Prevent mold growth and sanitize the area:

- Use a mild detergent solution to clean the floor

- For mold, use a mixture of water and white vinegar

- Dry the floor thoroughly after cleaning

- Sand and Refinish

For surface-level damage:

- Allow the floor to dry completely (may take several weeks)

- Sand the affected area to remove water stains

- Apply wood filler to any cracks or gaps

- Stain the repaired area to match the surrounding floor

- Apply a protective finish

- Replace Damaged Boards

For severe damage:

- Remove the damaged boards carefully

- Install new boards that match the existing flooring

- Sand and finish the new boards to blend with the rest of the floor

- Treat and Protect

To prevent future damage and extend the life of your wood floors:

- Apply a water-resistant sealant

- Use Rhino Wood Repair products to treat and protect the wood

Preventing Future Water Damage

An ounce of prevention is worth a pound of cure. Here are some tips to protect your wood floors:

- Regularly inspect for leaks in plumbing and appliances

- Use mats at entryways to catch water from shoes

- Clean up spills immediately

- Maintain proper indoor humidity levels (30-50%)

- Apply a protective coating every few years

FAQs About Water-Damaged Wood Floors

How long does it take for water to damage wood floors?

Water can begin to damage wood floors within hours of exposure, but visible signs may not appear for days or weeks.

Can I save severely water-damaged wood floors?

While severe damage often requires board replacement, many water-damaged floors can be saved with proper treatment and restoration techniques.

How can I tell if there’s water under my wood floor?

Look for signs like cupping, crowning, or a musty odour. You can also use a moisture meter for a more accurate assessment.

Is it necessary to replace the entire floor if only a portion is damaged?

Not always. Often, only the affected boards need to be replaced, and the rest of the floor can be restored through sanding and refinishing.

How can I prevent mold growth after water damage?

Act quickly to remove water, dry the area thoroughly, and use anti-mold products like those offered by Rhino Wood Repair.

Top 5 Rhino Wood Repair Products for Water-Damaged Floors

- Wood Hardener: Strengthens and reinforces weakened wood fibers

- Water-Resistant Sealant: Protects wood from future water damage

- Anti-Rot Treatment: Prevents and eliminates rot growth

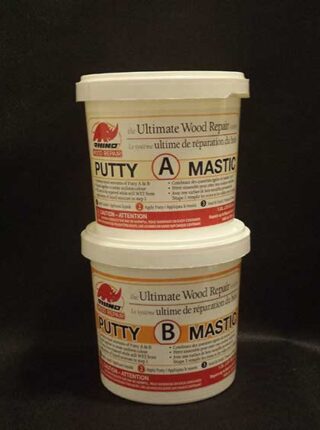

- Wood Filler Putty: Repairs cracks and gaps in damaged wood

- Protective Finish: Seals and beautifies restored wood floors

By following these steps and using high-quality products, you can effectively repair water-damaged wood floors and prevent future issues. Remember, the key to successful restoration is quick action and proper treatment.

About the Author:

Robin Pixner is the owner and chief chemist of Rhino Wood Repair, with over 30 years of experience in wood restoration and protection. As a leading expert in the field, Robin has developed innovative solutions to extend the life of wood and combat common issues like water damage and rot. His passion for preserving and restoring wood has led to the creation of Rhino Wood Repair’s line of high-performance products, trusted by professionals and homeowners alike.

by Robin Pixner | Jun 25, 2024 | News

Wood rot is a common problem that can significantly reduce the lifespan of wooden structures and furniture. Understanding how climate affects wood rot and implementing effective prevention strategies is crucial for maintaining the integrity of wood in various environments. In this comprehensive guide, we’ll explore the relationship between climate and wood rot, and provide practical solutions to protect your wooden assets.

Understanding Wood Rot

What is Wood Rot?

Wood rot is a form of decay caused by fungi that break down the cellular structure of wood. This process weakens the wood, compromising its strength and structural integrity.

Types of Wood Rot

- Dry rot

- Wet rot

- Soft rot

The Climate-Wood Rot Connection

How Climate Influences Wood Rot

Climate plays a significant role in the development and progression of wood rot. The following factors are particularly influential:

- Moisture levels

- Temperature

- Humidity

- Seasonal variations

High-Risk Climate Zones

Some climates are more conducive to wood rot than others. Areas with the following characteristics are particularly susceptible:

- High rainfall

- Tropical or subtropical regions

- Coastal areas with salt spray

- Regions with frequent temperature fluctuations

Prevention Strategies for Different Climates

Dry Climates

- Regular sealing and staining

- Proper ventilation to prevent moisture buildup

- Prompt repair of any water damage

Humid Climates

- Use of moisture-resistant wood species

- Application of water-repellent preservatives

- Installation of dehumidifiers in enclosed spaces

Coastal Areas

- Regular cleaning to remove salt deposits

- Use of marine-grade sealants

- Choosing rot-resistant wood species like cedar or redwood

5 Essential Steps to Prevent Wood Rot in Any Climate

- Regular inspections

- Proper drainage and water management

- Adequate ventilation

- Use of quality wood preservatives

- Prompt repairs and maintenance

Innovative Solutions: Rhino Wood Repair Products

At Rhino Wood Repair, we offer cutting-edge products designed to combat wood rot across various climates. Our products are formulated to:

- Penetrate deep into wood fibers

- Create a moisture-resistant barrier

- Strengthen existing wood structures

- Extend the life of wooden assets

Featured Product: Rhino PreTreat

Our flagship product, Rhino Wood PreTreat, is specially designed to:

- Reinforce weakened wood

- Prevent future rot

- Work effectively in diverse climates

FAQs About Climate and Wood Rot

- How quickly can wood rot develop in a humid climate?

In highly humid environments, wood rot can begin to develop within a few months if proper preventive measures are not taken.

- Can wood rot spread to other wooden structures?

Yes, wood rot fungi can spread through spores, potentially affecting nearby wooden structures if not addressed promptly.

- Are there any eco-friendly wood preservatives for preventing rot?

Yes, there are several eco-friendly options available, including borate-based preservatives and certain plant-based oils.

- How often should I inspect my wooden structures for signs of rot?

It’s recommended to conduct thorough inspections at least twice a year, ideally in spring and fall.

- Can painting wood prevent rot?

While paint can provide some protection, it’s not a foolproof solution. Proper sealing and preservative treatments are more effective for long-term rot prevention.

The Long-Term Benefits of Wood Rot Prevention

Investing in wood rot prevention strategies offers numerous advantages:

- Extended lifespan of wooden structures

- Reduced repair and replacement costs

- Improved safety and structural integrity

- Enhanced aesthetic appeal

- Increased property value

By implementing the strategies outlined in this guide and using high-quality products like those offered by Rhino Wood Repair, you can significantly reduce the risk of wood rot and protect your wooden assets for years to come.

About the Author

Robin Pixner is the owner and lead chemist at Rhino Wood Repair, with over 30 years of experience in wood preservation and repair. His expertise in developing innovative solutions for wood rot prevention has made him a respected figure in the industry. Robin’s commitment to creating effective, environmentally friendly products has helped countless homeowners and businesses protect their wooden structures across various climates.

by Robin Pixner | Jun 21, 2024 | News

Techniques for Repairing Weakened Wood

Wood is a versatile and beautiful material that has been used in construction and craftsmanship for centuries. However, over time, wood can become weakened due to various factors such as moisture, insect infestation, and decay. Fortunately, there are several techniques that can be used to repair weakened wood and restore its strength. In this blog post, we’ll explore some of these techniques and how they can help extend the life of your wooden structures.

Understanding Wood Deterioration

Before we dive into the techniques for repairing weakened wood, it’s important to understand the factors that contribute to wood deterioration. Some of the most common causes of wood decay include:

- Moisture: When wood is exposed to excessive moisture, it can become soft and prone to rot.

- Insect Infestation: Certain insects, such as termites and carpenter ants, can burrow into wood and cause significant damage.

- Fungal Growth: Fungi thrive in damp environments and can cause wood to rot and decay.

Techniques for Repairing Weakened Wood

1. Epoxy Consolidation

Epoxy consolidation is a technique that involves injecting epoxy resin into the weakened wood to fill voids and restore strength. This method is particularly effective for repairing large areas of decay or damage. The epoxy resin penetrates deep into the wood fibers, creating a strong bond that can withstand the elements.

2. Dutchman Repair

Dutchman repair is a technique that involves removing the damaged portion of the wood and replacing it with a new piece that matches the original grain and color. This method is often used for repairing small areas of damage, such as knots or cracks. The new piece of wood is carefully fitted and glued into place, creating a seamless repair.

3. Structural Reinforcement

In some cases, weakened wood may require structural reinforcement to restore its strength. This can be achieved through the use of steel plates, brackets, or other supportive elements. These reinforcements are typically hidden from view and can provide significant support to the weakened wood.

Preventing Wood Rot

While repairing weakened wood is important, preventing wood rot from occurring in the first place is even more critical. Here are some tips for preventing wood rot:

- Keep wood dry: Ensure that wooden structures are properly sealed and protected from moisture.

- Provide adequate ventilation: Allow air to circulate around wooden structures to prevent the buildup of moisture.

- Use rot-resistant wood species: Certain wood species, such as cedar and redwood, are naturally resistant to rot and decay.

- Apply protective coatings: Use paint, stain, or other protective coatings to seal the wood and prevent moisture from penetrating.

FAQs

How long does it take for wood to rot?

The speed at which wood rots depends on various factors, such as the type of wood, the level of moisture exposure, and the presence of fungi or insects. In general, untreated wood can begin to rot within a few months to a year if exposed to the elements.

Can rotted wood be repaired?

Yes, rotted wood can often be repaired using techniques such as epoxy consolidation or Dutchman repair. However, the extent of the damage will determine the feasibility and effectiveness of the repair.

How can I tell if my wood is rotting? Signs of wood rot include soft or spongy texture, visible decay or discolouration, and the presence of mushroom-like growth. If you suspect that your wood may be rotting, it’s important to address the issue promptly to prevent further damage.

About the Author

Robin Pixner, the owner and chemist behind Rhino Wood Repair, has over 30 years of experience in the field of wood restoration and preservation. With his expertise and commitment to quality, Rhino Wood Repair has become a trusted name in the industry, providing effective solutions for repairing weakened wood and preventing wood rot. Robin’s products are designed to extend the life of wooden structures, ensuring their beauty and strength for years to come. See our wood treatment products here.

by Robin Pixner | Jun 18, 2024 | News

Outdoor wood structures, such as decks, fences, and pergolas, add beauty and functionality to your property. However, exposure to the elements can lead to deterioration and decay over time. Proper maintenance is crucial to extend the life of your wooden structures and keep them looking their best. In this blog post, we’ll explore expert tips from Robin Pixner, Owner and Chemist at Rhino Wood Repair, on how to maintain your outdoor wood structures year-round.

The Importance of Regular Inspection

The first step in maintaining your outdoor wood structures is to conduct regular inspections. Look for signs of damage, such as:

- Cracks or splits in the wood

- Loose or missing fasteners

- Discolouration or stains

- Soft or spongy areas (indicating rot)

By identifying issues early on, you can address them before they escalate into more significant problems.

Cleaning and Sealing

To keep your outdoor wood looking its best, clean it annually using a mild detergent and a soft-bristled brush. Avoid using pressure washers, as they can damage the wood fibers. After cleaning, allow the wood to dry completely before moving on to the next step.

Applying a Protective Sealant

Once your wood is clean and dry, apply a high-quality sealant to protect it from moisture, UV rays, and other environmental factors. Look for a product that penetrates deep into the wood, such as Rhino Wood Repair’s Wood Sealer. This will help prevent cracking, splitting, and warping.

Addressing Wood Rot and Decay

If you notice signs of wood rot or decay during your inspections, it’s essential to address the issue promptly. Robin Pixner, with his 30+ years of experience, recommends using Rhino Wood Repair’s Wood Hardener and Wood Filler to restore and strengthen damaged wood. These products penetrate deep into the wood fibers, filling voids and creating a solid surface that can be sanded and painted.

Seasonal Maintenance Tips for Wood

Spring

- Inspect your wood structures for any damage that may have occurred during the winter months

- Clean and seal your wood to prepare it for the upcoming outdoor season

Summer

- Regularly clean your wood surfaces to prevent the buildup of dirt and grime

- Monitor your wood for signs of insect activity or damage

Fall

- Remove fallen leaves and debris from your wood structures to prevent moisture retention

- Inspect and repair any damage before the winter season arrives

Winter

- Remove snow and ice from your wood structures to prevent moisture damage

- Cover or store outdoor furniture to protect it from harsh winter weather

FAQs

How often should I clean my outdoor wood structures?

It’s recommended to clean your outdoor wood structures at least once a year, typically in the spring or fall.

Can I use a pressure washer to clean my wood surfaces?

While pressure washers can be effective, they can also damage wood fibers if used improperly. It’s best to use a mild detergent and a soft-bristled brush for cleaning.

How can I tell if my wood has rot or decay?

Signs of wood rot include soft or spongy areas, discoloration, and a musty smell. If you notice any of these signs, it’s important to address the issue promptly.

How often should I apply a sealant to my outdoor wood?

The frequency of sealing depends on the type of wood and the environmental conditions it’s exposed to. As a general rule, it’s a good idea to reseal your wood every 1-3 years. However with Rhino wood repair products, your wood asset lifespan increases by over double that!

About the Author

Robin Pixner is the Owner and Chemist at Rhino Wood Repair, a company specializing in products that repair wood and prevent wood rot. With over 30 years of experience, Robin has developed a deep understanding of wood preservation and maintenance techniques. His expertise has helped countless homeowners extend the life of their outdoor wood structures, ensuring they remain beautiful and functional for years to come.

Summarizing How to Maintain Outdoor Wood Structures Year-Round

Maintaining your outdoor wood structures year-round is essential for preserving their beauty, functionality, and longevity. By following the expert tips outlined in this blog post, you can keep your wooden decks, fences, and pergolas in top condition. Remember to inspect regularly, clean and seal annually, and address any signs of damage or decay promptly. With the right products, like those offered by Rhino Wood Repair, and a commitment to regular maintenance, your outdoor wood structures will continue to enhance your property for years to come.

by Robin Pixner | Jun 14, 2024 | News

PRESERVING THE BEAUTY AND INTEGRITY

Boat Wood Maintenance Products

About the Author

Robin Pixner, the Owner and Chemist at Rhino Wood Repair, is a true industry veteran with over three decades of experience in the field of wood preservation. His passion for boating and his deep understanding of chemistry have led him to develop cutting-edge solutions that have transformed the way boat owners approach wood maintenance.

Understanding the Challenges of Boat Wood Maintenance

Boats endure a unique set of challenges when it comes to wood preservation. The constant exposure to moisture, saltwater, and ultraviolet radiation can wreak havoc on even the most resilient timber. Left unchecked, these elements can lead to:

- Wood rot

- Fading and discolouration

- Cracking and splitting

- Structural weakness

Fortunately, with the right approach and products, you can safeguard your boat’s wood against these formidable foes.

The Secret to A Long-Lasting Wood Boat

Enter Rhino Wood Repair, a pioneering company that has revolutionized the way we protect and maintain boat wood. With over 30 years of experience under the helm of Owner and Chemist Robin Pixner, Rhino Wood Repair has developed a suite of innovative products designed to tackle wood rot and extend the lifespan of your boat’s timber.

The Rhino Wood Repair Advantage

What sets Rhino Wood Repair apart is their proprietary formula, which not only repairs existing wood rot but also fortifies the wood against future damage. Their products penetrate deep into the wood fibers, creating a protective barrier that safeguards your boat from the ravages of moisture, saltwater, and UV radiation.

Key Benefits of Rhino Wood Repair Products

- Arrest and reverse wood rot

- Prevent future rot and decay

- Restore structural integrity

- Enhance water resistance

- Protect against UV damage

- Easy application and long-lasting results

The Rhino Wood Repair Process: A Step-by-Step Guide

Maintaining your boat’s wood with Rhino Wood Repair is a straightforward process that will yield exceptional results. Here’s a step-by-step guide to help you get started:

- Inspect and Prepare: Begin by thoroughly inspecting your boat’s wood for signs of rot, discolouration, or structural damage. Once identified, clean and prepare the affected areas for treatment.

- Apply the Repair Solution: Follow the instructions provided by Rhino Wood Repair to apply their specialized repair solution to the affected areas. This solution will penetrate deep into the wood, halting and reversing the rot.

- Seal and Protect: After the repair solution has had time to work its magic, apply Rhino Wood Repair’s protective sealant. This sealant creates a water-resistant barrier that shields your boat’s wood from future damage.

- Maintain and Enjoy: With your boat’s wood now fortified and protected, establish a regular maintenance routine to ensure long-lasting results. Rhino Wood Repair’s products will keep your boat looking as good as new for years to come.

“keeping your boat’s wood in pristine condition can be a daunting task, especially when faced with the relentless onslaught of the elements.”

For boat enthusiasts, there’s nothing quite like the charm and elegance of a well-maintained wooden vessel. However, keeping your boat’s wood in pristine condition can be a daunting task, especially when faced with the relentless onslaught of the elements. Fear not, as this comprehensive guide will equip you with the knowledge and strategies to ensure your boat’s wood remains a sight to behold for years to come.

Summarizing the Important of Boat Wood Maintenance

Maintaining the beauty and integrity of your boat’s wood is a responsibility that should not be taken lightly. With Rhino Wood Repair’s innovative products and Robin Pixner’s decades of expertise, you can rest assured that your boat’s wood will remain a source of pride and enjoyment for years to come. Invest in the longevity of your vessel today and experience the unparalleled satisfaction of pristine, well-preserved boat wood.

Frequently Asked Questions

Can Rhino Wood Repair products be used on any type of wood?

Yes, Rhino Wood Repair’s solutions are compatible with a wide range of wood types, including teak, mahogany, oak, and more. Their formulas are specifically designed to penetrate and protect various wood fibers effectively.

How long do the effects of Rhino Wood Repair products last?

With proper application and regular maintenance, the effects of Rhino Wood Repair products can last for several years, depending on the severity of the initial damage and the exposure conditions.

Are Rhino Wood Repair products safe for the environment?

Absolutely. Rhino Wood Repair takes environmental sustainability seriously, and their products are formulated to be eco-friendly and biodegradable, ensuring minimal impact on the surrounding ecosystem.

Can Rhino Wood Repair products be used on boats that are already in service?

Yes, Rhino Wood Repair’s solutions are designed to be used on both new and existing boats, making them ideal for ongoing maintenance and repair.

by Robin Pixner | Jun 13, 2024 | News

As a homeowner, maintaining the aesthetic appeal and structural integrity of your property is a top priority. One area that often requires attention is the wood siding, which can suffer from rot, weathering, and other forms of damage over time. Fortunately, there are effective wood siding repair products available to help breathe new life into your home’s exterior. In this article, we’ll explore the top options from Rhino Wood Repair, a company with over 30 years of experience in wood preservation.

Understanding Wood Rot and Its Consequences

Wood rot, caused by fungal decay, is a common issue that can compromise the strength and appearance of your wood siding. Left unchecked, it can lead to costly repairs and even structural damage. Factors like moisture, poor ventilation, and lack of proper maintenance can accelerate the rotting process, making it crucial to address the problem promptly.

Rhino Wood Repair: A Trusted Name in Wood Preservation

Rhino Wood Repair, founded by chemist Robin Pixner, has been at the forefront of wood repair and preservation for over three decades. Their innovative products are designed to not only repair existing damage but also prevent future rot, extending the lifespan of your wood siding.

Top Rhino Wood Repair Products for Wood Siding

1. Rot Repair Epoxy: This two-part epoxy system is specially formulated to repair and restore rotted or damaged wood. It consolidates the remaining sound wood and provides a durable, long-lasting repair.

2. Wood Hardener: If your wood siding is showing signs of softening or deterioration, Rhino Wood Repair’s Wood Hardener can help. It penetrates deep into the wood fibers, restoring strength and stability.

3. Wood Preserver: Prevention is key when it comes to wood rot. Rhino Wood Repair’s Wood Preserver is a concentrated formula that protects against fungal decay, insect damage, and moisture intrusion, ensuring your wood siding stays in top condition for years to come.

The Benefits of Using Rhino Wood Repair Products

- Proven track record of over 30 years in the industry

- Environmentally friendly and low-odor formulations

- Easy-to-use products suitable for DIY projects

- Cost-effective solutions compared to full replacement

- Long-lasting results, extending the life of your wood siding

Frequently Asked Questions

Can I use these products on any type of wood siding?

Yes, Rhino Wood Repair products are compatible with various types of wood siding, including cedar, redwood, and pressure-treated wood.

How long do the repairs typically last?

With proper application and maintenance, repairs made with Rhino Wood Repair products can last for several years, protecting your investment.

Are these products safe for the environment?

Absolutely. Rhino Wood Repair takes pride in offering environmentally friendly and low-odor formulations, ensuring minimal impact on the surroundings.

About the Author

This blog post was written in collaboration with Robin Pixner, the founder and chemist behind Rhino Wood Repair. With over 30 years of experience in the wood repair and preservation industry, Robin has dedicated his career to developing innovative solutions that extend the lifespan of wood structures. His products, including Liquid A/B rot treatment, and wood restoration putty have become trusted names among homeowners and professionals alike.

At Rhino Wood Repair, Robin and his team are committed to providing high-quality, environmentally conscious products that not only repair existing damage but also prevent future issues. Their expertise and passion for wood preservation shine through in every product they offer.

If you’re looking to revive the beauty and structural integrity of your wood siding, trust the experts at Rhino Wood Repair. Their proven solutions will help you protect your investment and enjoy the timeless charm of wood for years to come.

by Robin Pixner | Jun 7, 2024 | News

The Importance of Wood Repair for Your Luxury Getaway

Owning a luxury cabin or vacation home is a dream for many, offering a serene escape from the hustle and bustle of daily life. However, maintaining the beauty and structural integrity of these wooden havens requires diligent care and attention, particularly when it comes to combating the ever-present threat of wood rot and damage. This is where professional wood repair services come into play, ensuring that your cherished retreat remains a picture-perfect oasis for years to come.

Rhino Wood Repair: Experts in Preserving Wooden Sanctuaries

When it comes to safeguarding the longevity of your luxury cabin or vacation home, Rhino Wood Repair stands out as the premier solution. With over three decades of experience, owner and chemist Robin Pixner has honed his expertise in wood repair and preservation, developing innovative products that not only repair existing damage but also prevent future deterioration.

The Rhino Wood Repair Advantage

- Unparalleled Expertise: With 30+ years in the industry, Robin Pixner’s vast knowledge ensures that every wood repair project is approached with the utmost care and precision.

- Cutting-Edge Solutions: Rhino Wood Repair’s proprietary formulations are specifically designed to address the unique challenges of wood repair in luxury cabins and vacation homes, ensuring long-lasting results.

- Environmental Responsibility: Their products are eco-friendly, allowing you to preserve the natural beauty of your wooden sanctuary while minimizing environmental impact.

- Comprehensive Services: From minor repairs to extensive restorations, Rhino Wood Repair offers a comprehensive range of services tailored to your specific needs.

5 Signs Your Luxury Cabin or Vacation Home Needs Professional Wood Repair

- Visible Rot or Decay: Keep an eye out for soft, crumbly, or discoloured wood, as these are telltale signs of wood rot that require immediate attention.

- Structural Instability: If you notice sagging beams, floors, or walls, it could indicate advanced wood deterioration, compromising the structural integrity of your property.

- Insect Infestation: Pests like termites and carpenter ants can wreak havoc on wooden structures, leaving behind tunnels and weakened wood.

- Moisture Issues: Excessive moisture, whether from leaks, humidity, or poor ventilation, can create an ideal environment for wood rot and damage to thrive.

- Aesthetic Concerns: While cosmetic issues like peeling paint or discoloration may seem minor, they could be early indicators of underlying wood damage that requires professional attention.

Frequently Asked Questions

How often should I have my luxury cabin or vacation home inspected for wood damage?

It’s recommended to have a professional wood repair service conduct an inspection at least once a year, or immediately if you notice any signs of damage or deterioration.

Can wood repair services prevent future damage?

Absolutely! Rhino Wood Repair offers specialized treatments and products that not only repair existing damage but also fortify the wood against future rot, insect infestations, and moisture-related issues.

How long does the wood repair process typically take?

The duration of the repair process can vary depending on the extent of the damage and the scope of the project. Minor repairs may be completed in a day or two, while more extensive restorations could take several weeks.

Are Rhino Wood Repair’s products safe for indoor use?

Yes, their products are specially formulated to be low in toxicity and safe for indoor use, ensuring the health and well-being of your family and guests.

About the Author

With over 30 years of experience in the wood repair and preservation industry, Robin Pixner, the owner and chemist at Rhino Wood Repair, has become a trusted name in the field. His passion for protecting the beauty and longevity of wooden structures has driven him to develop innovative solutions that combat wood rot, moisture damage, and insect infestations. Rhino Wood Repair’s products are the result of years of research and a deep understanding of the unique challenges faced by luxury cabins and vacation homes.

by Robin Pixner | Jun 7, 2024 | News

What is a Hardwood Floor Repair Kit?

A hardwood floor repair kit is an essential toolkit for homeowners and contractors to fix scratches, dents, cracks, and other damage to hardwood floors. These kits typically contain wood filler sticks, color putty, markers, and tools to seamlessly blend repairs into the existing floor.

Why Choose Rhino Wood Repair Kits?

Rhino Wood Repair offers premium hardwood floor repair solutions formulated by chemist Robin Pixner, who has over 30 years of experience in the wood repair industry. Their products are designed to prevent and repair wood rot, extending the lifespan of your hardwood floors.

Key Benefits of Rhino Wood Repair Kits

- Easy to use for DIY repair kits

- Provide long-lasting and durable results

- Color-matched to blend in seamlessly

- Prevent further deterioration and wood rot

- More affordable than replacing floors

Common Hardwood Floor Problems and How to Fix Them

Scratches and Dents

Scratches and dents are inevitable with hardwood floors, especially in high-traffic areas. To fix these:

- Clean the area thoroughly

- Use a wood filler putty to fill the scratch/dent

- Lightly sand and wipe clean

- Apply a color marker matched to your floor’s stain

Cracks and Gaps

As floors age and settle, cracks and gaps can form between boards. Here’s how to repair them:

- Vacuum out any debris in the crack/gap

- Apply a wood filler or flexible acrylic caulk

- Use a putty knife to level the filler flush with the floor

- Wipe away any excess and allow to fully dry

Water Damage and Stains

Water stains and damage can warp and discolor wood floors. To address these issues:

- Thoroughly dry out any wet areas

- Lightly sand the stained area to remove the top layer

- Use a wood bleach or oxalic acid solution

- Apply wood filler and stain to match

FAQ:

How long do Rhino Wood Repair products last?

When applied correctly, Rhino’s wood fillers and repair products can last for years without chipping, cracking or fading. Their proprietary formulas are incredibly durable.

Are the repairs permanent?

While not permanent, Rhino’s repairs are semi-permanent and can extend the life of your floors for 5-10 years before needing replacement.

Can repairs be done on any type of hardwood floor?

Yes, Rhino’s color-matched products work on all types of hardwood including oak, maple, cherry, walnut and more.

How soon can I walk on the repaired floors?

You can walk on the floors 24-48 hours after repairs, but avoid heavy furniture for 3-5 days to allow proper curing.

The Top 5 Reasons to Use Rhino Wood Repair Kits:

- Easy DIY application without special tools

- Save money versus replacing floors

- Prevent further wood rot and deterioration

- Long-lasting and durable repairs

- Color-matched to blend in seamlessly

About the Author

Robin Pixner is the founder and lead chemist at Rhino Wood Repair with over 30 years developing wood repair and preservation products. A true pioneer in the industry, Robin’s proprietary formulations prevent and repair wood rot while restoring floors to their original beauty.

by Robin Pixner | Jun 7, 2024 | News

Owning a wooden deck is a great way to enjoy the outdoors from the comfort of your home. However, wooden decks require proper maintenance to keep them looking beautiful and functioning safely for years to come. With some basic care and the right products, you can significantly extend the lifespan of your treasured deck. Follow these tips from the experts at Rhino Wood Repair.

Prevent and Repair Wood Rot

The #1 Enemy: Moisture

One of the biggest threats to the structural integrity of a wood deck is rot caused by excess moisture penetration. This can happen from:

- Humidity and rain exposure

- Clogged drainage on or around the deck

- Poor ventilation under the deck

Once moisture gets trapped in the wood, fungi start to grow and cause the decay known as wood rot. This severely compromises the load-bearing ability of deck boards and framing.

Inspection is Key

Regularly inspecting all areas of your deck is crucial for catching rot early when it is easier to remedy. Use a flathead screwdriver to poke exterior wood surfaces – if the tool easily penetrates more than 1/8 inch, rot is likely present. Also check for:

- Spongy or crumbly wood texture

- Dipping or sagging deck boards

- Brown, gray or white discolouration

Repair Rotted Wood with Proven Products

If you do discover rotted wood areas, don’t fret – Rhino Wood Repair has professional-grade products to restore the damage. The company’s epoxy wood restorers actually get harder than original wood once cured, rebuilding structural strength.

Proper Cleaning and Sealing

Cleaning and sealing your deck on a regular schedule is one of the easiest ways to protect against wood rot and premature aging. Build these steps into your annual deck maintenance:

- Spring Cleaning – Use a deck cleaner solution and stiff brush to remove built-up grime, mildew, and debris from all deck surfaces.

- Sanding – For optimum new seal penetration, lightly sand after cleaning.

- Sealing – Apply a fresh coat of highly-rated exterior wood sealer or stain. This protective coating blocks moisture absorption.

- Winter Prep – At season’s end, clean off Fall debris and re-seal any worn areas before Winter arrives.

Consider a Waterproof Deck System

For new deck builds or major restorations, maximize protection by installing an integrated waterproof decking system like Rhino’s DuraDeck. This UV-resistant membrane seamlessly covers the entire walking surface and is guaranteed against leaks for decades. No more dealing with rot!

Extend with Add-On Features

In addition to basic wood care, strategically adding the right accessories to your deck design can vastly improve its longevity:

- Pergolas or awnings shield against harsh sun & rain

- Deck drainage systems promote water run-off

- Under-deck drainage and ventilation panels prevent moisture build-up below

- Benches, planters & railings protect edges & stairs

Frequently Asked Questions About How to Extend the Life of Wooden Decks?

How often should I re-seal or re-stain my deck?: Most professional deck contractors recommend cleaning and re-sealing wood decks every 1-2 years depending on weather exposure. However with Rhino wood repair products, your wooden deck lifespan increases by over double that!

Can rotted boards just be replaced?: Spot board replacement is possible with minor, localized rot. But widespread fungal decay means the entire deck’s structural integrity could be compromised, requiring full demolition and re-building.

Is composite decking better than wood?: Composite and PVC deck boards are rot-resistant, but the framing underneath can still develop fungal rot over time. Investing in complete wood repair, sealing and drainage is recommended for all deck materials.

About the Author – How to Extend the Life of Wooden Decks?

This deck life-extension guide was created in partnership with Robin Pixner, Owner and Chemist at Rhino Wood Repair. With over 30 years of experience developing industrial-strength wood repair products, Robin’s epoxy and waterproof systems give contractors and homeowners the longest lasting defense against wood rot and deterioration. Rhino’s proven solutions can be found at major home improvement retailers across North America.

by Robin Pixner | Jun 7, 2024 | News

Wooden furniture adds warmth, character, and timeless beauty to any home. However, without proper care and maintenance, these treasured pieces can succumb to wear and tear, leaving them looking dull, damaged, and worn out. In this comprehensive guide, we’ll share expert tips and tricks to help you make your wooden furniture last for years to come.

The Importance of Maintaining Wooden Furniture

Wooden furniture is an investment that can be passed down through generations if cared for properly. Not only does regular maintenance enhance the furniture’s aesthetic appeal, but it also safeguards its structural integrity and prevents costly repairs or replacements down the line.

Cleaning and Dusting: The Foundation of Wood Care

Dust Regularly

Dust is a wooden furniture’s worst enemy. It accumulates in crevices and can scratch the surface when rubbed against it. Use a soft, lint-free cloth or a microfibre duster to remove dust from your furniture regularly.

Choose the Right Cleaning Products

Avoid using harsh chemicals, abrasive cleaners, or furniture polish containing silicone, as these can damage the wood’s finish. Instead, opt for mild soap and water or specialized wood cleaners formulated for your specific furniture type.

Protecting Your Wooden Furniture

Apply a Protective Finish

A high-quality finish, such as lacquer, varnish, or polyurethane, acts as a barrier against moisture, spills, and scratches. If your furniture’s finish is starting to wear off, consider refinishing it to restore its protective layer.

Use Coasters and Placemats

Moisture and heat can cause unsightly rings and discolouration on unprotected wood surfaces. Always use coasters and placemats to prevent these damaging effects.

Preventing Wood Rot and Decay

Wood rot and decay can severely compromise the structural integrity of your furniture, leading to costly repairs or even the need for replacement. To prevent this, consider the following:

Control Humidity Levels

Excessive moisture can lead to wood rot and mold growth. Use a dehumidifier or air conditioner to maintain optimal humidity levels in your home, typically between 30% and 50%.

Address Water Damage Promptly

If your wooden furniture gets wet, act quickly. Dry it thoroughly with a clean cloth or towel, and consider using a specialized wood repair product to address any potential water damage.

Top 3 Wood Repair and Maintenance Products by Rhino Wood Repair

- Wood Restorer: A powerful formula that restores the natural beauty of weathered, faded, and discoloured wood, reviving its original luster.

- Wood Epoxy Putty: An easy-to-use, two-part epoxy putty that fills cracks, holes, and missing pieces in wooden furniture, providing a long-lasting repair.

- Wood Preservative: A protective coating that safeguards wood against moisture, UV rays, and other environmental factors, prolonging its lifespan.

Frequently Asked Questions

How often should I dust my wooden furniture?: Aim to dust your wooden furniture at least once a week, or more frequently if it’s located in a high-traffic area or a dusty environment.

Can I use regular household cleaners on my wooden furniture?: It’s best to avoid using harsh chemicals or abrasive cleaners, as they can damage the wood’s finish. Stick to mild soap and water or specialized wood cleaners.

How do I know if my wooden furniture needs refinishing?: If the finish is cracked, peeling, or severely scratched, it’s time to consider refinishing your furniture to protect the wood and restore its appearance.

Can wood rot be repaired?: Yes, in many cases, wood rot can be addressed using specialized wood repair products like those offered by Rhino Wood Repair. However, severe cases may require professional assistance or replacement.

About the Author

This blog post was written in consultation with Robin Pixner, the Owner and Chemist at Rhino Wood Repair. With over 30 years of experience in the industry, Robin has dedicated his career to developing innovative and effective products that repair and preserve wood, extending its lifespan and beauty. Rhino Wood Repair’s line of products is trusted by homeowners, woodworkers, and professionals alike, providing long-lasting solutions for various wood repair and maintenance needs.

By following the tips and recommendations outlined in this guide and utilizing Rhino Wood Repair’s products, you can ensure that your cherished wooden furniture remains a stunning centrepiece in your home for years to come.

by Robin Pixner | May 24, 2024 | News

Protect Your Shed with Effective Wood Treatment: A Comprehensive Guide

Are you tired of dealing with wood rot, unsightly discolouration, and structural damage to your beloved shed? Look no further than Rhino Wood Repair – the ultimate solution for preserving the longevity and aesthetic appeal of your wooden structures.

The Importance of Wood Treatment for Sheds

Sheds are often overlooked when it comes to maintenance, but they play a crucial role in safeguarding our tools, equipment, and outdoor belongings. Neglecting to treat the wood can lead to costly repairs or even the need for a complete replacement. By investing in proper wood treatment, you can extend the lifespan of your shed and save money in the long run.

Common Wood Problems Faced by Shed Owners

- Wood Rot: Caused by fungi that feed on the cellulose and lignin in wood, wood rot can weaken the structural integrity of your shed, leading to potential collapse.

- Insect Infestations: Termites, carpenter ants, and other wood-boring insects can wreak havoc on untreated wood, leaving behind unsightly tunnels and compromising the shed’s structural stability.

- UV Damage: Prolonged exposure to sunlight can cause wood to become brittle, discolored, and prone to cracking and splitting.

- Moisture Damage: Excess moisture can lead to warping, swelling, and the growth of mold and mildew, ultimately degrading the wood’s integrity.

The Rhino Wood Repair Advantage

Rhino Wood Repair offers a comprehensive range of wood treatment products that address these common issues, providing shed owners with a reliable and long-lasting solution. Their innovative formulations are designed to:

- Eliminate and prevent wood rot

- Deter insect infestations

- Protect against UV damage

- Resist moisture damage

By utilizing Rhino Wood Repair’s cutting-edge products, you can ensure your shed remains in pristine condition for years to come.

Frequently Asked Questions (FAQs)

- How often should I treat my shed with Rhino Wood Repair products?

The frequency of treatment depends on factors such as the shed’s age, exposure to the elements, and the severity of existing damage. Generally, it’s recommended to treat your shed annually for optimal protection.

- Can Rhino Wood Repair products be used on other wooden structures besides sheds?

Absolutely! Rhino Wood Repair’s products are versatile and can be applied to various wooden structures, including fences, decks, pergolas, and even wooden furniture.

- Are Rhino Wood Repair products environmentally friendly?

Yes, Rhino Wood Repair takes pride in offering eco-friendly solutions that are safe for both people and the planet. Their products are formulated to be low in volatile organic compounds (VOCs) and biodegradable.

Top 5 Benefits of Using Rhino Wood Repair Products

- Long-lasting protection against wood damage

- Easy application process

- Cost-effective solution compared to replacement

- Environmentally friendly formulations

- Enhances the aesthetic appeal of your shed

Take Action Now!

Don’t let wood rot, insect infestations, or weathering take a toll on your beloved shed. Trust Rhino Wood Repair’s proven solutions to preserve and protect your investment. See our range of wood treatment products and take the first step towards a worry-free, beautifully maintained shed.

Remember, by investing in proper wood treatment, you’re not only safeguarding your shed but also contributing to a more sustainable future for your outdoor spaces. Embrace the power of Rhino Wood Repair and enjoy a lifetime of worry-free shed ownership.

About the Author

This blog post is brought to you by Robin Pixner, the owner and chemist behind Rhino Wood Repair. With years of expertise in the field, Robin has dedicated his career to developing innovative and effective wood treatment products that repair and protect wood from the ravages of time and the elements.

by Robin Pixner | May 21, 2024 | News

How to Repair Rotted Wood on a Log Cabin: A Comprehensive Guide

Looking to restore your log cabin to its former glory? Dealing with rotted wood can be a daunting task, but fear not! With the right approach and the help of experts like Rhino Wood Repair, you can breathe new life into your beloved cabin. In this comprehensive guide, we’ll explore the ins and outs of repairing rotted wood, ensuring your log cabin stands tall for years to come.

Understanding Wood Rot: The Silent Culprit

Before diving into the repair process, it’s crucial to understand the root cause of wood rot. Wood rot is primarily caused by fungal organisms that thrive in damp, humid environments. These fungi feed on the cellulose and lignin components of wood, causing it to weaken and eventually crumble. See here for best wood rot repair products.

Common Causes of Wood Rot in Log Cabins

- Excessive moisture from leaks, condensation, or poor ventilation

- Improper construction or maintenance practices

- Exposure to harsh weather conditions

- Insect infestations that damage the wood’s integrity

The Step-by-Step Repair Process

Repairing rotted wood on a log cabin requires a systematic approach to ensure long-lasting results. Here’s a step-by-step guide to help you tackle the task:

- Identify and Remove Rotted Wood: Inspect your log cabin thoroughly and identify areas with significant rot. Use a screwdriver or awl to probe the wood and determine the extent of the damage. Remove all rotted wood sections, taking care not to damage the surrounding healthy wood.

- Prepare the Area: Once the rotted wood is removed, clean the affected area thoroughly. Use a wire brush or sandpaper to remove any remaining decayed material, ensuring a clean surface for the repair process.

- Apply a Wood Consolidant: Products like Rhino Wood Repair’s wood consolidants can help strengthen and solidify the remaining wood fibers, providing a stable base for the repair.

- Fill the Void: After the wood consolidant has cured, it’s time to fill the void left by the rotted wood. Rhino Wood Repair offers a range of epoxy wood repair products that can be easily molded and shaped to match the contours of your log cabin.

- Finish and Seal: Once the epoxy repair has cured, sand the area to achieve a smooth finish. Apply a protective sealant or stain to match the surrounding wood and prevent future moisture intrusion.

Rhino Wood Repair: Your Partner in Cabin Restoration

When it comes to repairing rotted wood on log cabins, Rhino Wood Repair is a trusted name in the industry. Founded by Robin Pixner, a chemist with years of experience in wood preservation, Rhino Wood Repair offers a range of innovative products designed to extend the life of wood structures.

About the Author: Robin Pixner

Robin Pixner, the founder and chemist behind Rhino Wood Repair, has dedicated his career to developing cutting-edge solutions for wood preservation and repair. With a deep understanding of the challenges faced by log cabin owners, Robin has formulated specialized products that not only repair rotted wood but also prevent future rot, ensuring your cabin remains a cherished home for generations to come.

FAQs: Addressing Common Concerns

- How long does the repair process take? The duration of the repair process can vary depending on the extent of the damage and the size of the area being repaired. However, with Rhino Wood Repair’s fast-curing products, you can expect a significant portion of the work to be completed within a few days.

- Is the repair permanent? While no repair is truly permanent, the products and techniques used by Rhino Wood Repair are designed to provide long-lasting solutions. With proper maintenance and care, your repaired log cabin can withstand the test of time.

- Can I do the repairs myself? While some minor repairs can be tackled as a DIY project, it’s recommended to seek professional assistance for extensive or structural damage. Rhino Wood Repair offers expert guidance and training to ensure the repairs are performed correctly and safely.

- How much will the repair cost? The cost of repairing rotted wood on a log cabin can vary depending on the extent of the damage, the products used, and the labor involved. Rhino Wood Repair provides competitive pricing and can provide a detailed estimate based on your specific needs.

The Ultimate Checklist for Log Cabin Wood Repair

To ensure a successful repair process, follow this ultimate checklist:

- Inspect your log cabin thoroughly for signs of wood rot

- Gather the necessary tools and materials, including Rhino Wood Repair products

- Remove all rotted wood sections carefully

- Clean and prepare the affected area

- Apply a wood consolidant for added strength

- Fill the void with Rhino Wood Repair’s epoxy wood repair products

- Sand and finish the repaired area to match the surrounding wood

- Apply a protective sealant or stain

- Maintain and inspect your log cabin regularly to prevent future rot

By following these steps and utilizing the expertise of Rhino Wood Repair, you can breathe new life into your property with proper log home restoration, ensuring it remains a cherished retreat for years to come.

by Robin Pixner | May 17, 2024 | News

If you have an old fence that’s been weathered by the elements, you might be wondering if it’s possible to give it a fresh new look with a coat of stain. While staining an old fence is certainly an option, there are a few important factors to consider to ensure the best possible results. In this comprehensive guide, we’ll explore the steps involved in staining an old fence, the benefits of using a quality stain, and how incorporating Rhino Wood Repair products can significantly enhance the protection and longevity of your fence.

Preparing an Old Fence for Staining

Before you can apply a new stain to your old fence, proper preparation is crucial for optimal adhesion and long-lasting results:

Cleaning and Stripping

- Thoroughly clean the fence surface to remove dirt, grime, and any loose or peeling paint or stain.

- Use a chemical stripper or sanding to remove any remaining old stain or paint, ensuring a clean, bare wood surface.

Addressing Damage and Repairs

- Inspect the fence for any damaged, rotted, or loose boards and replace them as needed.

- Consider incorporating Rhino Wood Repair products to address any weakened or damaged wood before staining, ensuring a strong and durable foundation.

Sanding and Final Preparation

- Sand the entire fence surface to create a rough texture for better stain adhesion.

- Remove any remaining dust or debris from the sanding process.

Choosing the Right Stain for Fence

When it comes to staining an old fence, selecting the right stain is crucial for achieving the desired look and longevity. Here are some factors to consider:

Stain Types

- Oil-based stains: Provide superior penetration and water repellency but can be more difficult to apply and maintain.

- Water-based stains: Easier to apply and clean up, but may not offer the same level of protection as oil-based stains.

- Semi-transparent stains: Allow the natural wood grain to show through while providing some UV protection.

- Solid stains: Offer a more opaque finish and better UV protection but can obscure the wood’s natural beauty.

Stain Colours and Finishes

Consider the desired final look for your fence and choose a stain color and finish that complements your home’s exterior and landscaping.

The Benefits of Using Rhino Wood Repair Products Before Staining

While staining an old fence can breathe new life into its appearance, addressing any underlying wood damage is crucial for long-lasting results. This is where Rhino Wood Repair products can make a significant difference:

- Strengthen Weakened Wood: Rhino Wood Repair products are formulated to penetrate deep into the wood fibers, strengthening and reinforcing weakened or damaged areas.

- Enhance Stain Adhesion: By addressing any underlying wood issues, Rhino Wood Repair products create a solid foundation for the stain to adhere to, ensuring better protection and longevity.

- Extend the Life of Your Fence: By incorporating Rhino Wood Repair products into your fence maintenance routine, you can significantly extend the lifespan of your fence, reducing the need for frequent replacements and saving you money in the long run.

FAQs about Staining Old Fences

How long will a stained fence last?

The longevity of a stained fence depends on various factors, including the quality of the stain, the fence’s exposure to the elements, and the condition of the wood. With proper preparation, high-quality stain, and regular maintenance, a stained fence can last anywhere from 3-5 years before requiring a fresh coat.

Can I stain over an old, weathered fence?

While it’s possible to stain over an old, weathered fence, it’s generally not recommended. The old stain or paint should be removed first to ensure proper adhesion and penetration of the new stain.

Can I use the same stain on both wood and vinyl fences?

No, it’s important to use stains specifically formulated for the type of material you’re working with. Wood stains are not suitable for vinyl fences and vice versa.

How long do I need to wait before staining a new fence?

It’s generally recommended to wait at least 6 months before staining a new, pressure-treated wood fence. This allows the wood to dry and cure properly, ensuring better stain penetration and adhesion.

Top Tips for Staining an Old Fence:

- Thoroughly clean and prepare the fence surface for optimal stain adhesion.

- Address any damaged or weakened wood with Rhino Wood Repair products before staining.

- Choose a high-quality, reputable stain suitable for your climate and exposure conditions.

- Follow the manufacturer’s instructions carefully for proper application and coverage rates.

- Maintain your stained fence by regularly cleaning, inspecting, and re-staining as needed.

About the Author

This comprehensive guide on staining an old fence was brought to you by Rhino Wood Repair, a company dedicated to providing top-quality wood repair solutions. Our founder and chemist, Robin Pixner, has years of experience in the industry and a passion for helping homeowners and professionals alike achieve flawless woodwork.

At Rhino Wood Repair, we understand the importance of preserving the beauty and longevity of wood surfaces. Our products are carefully formulated to ensure exceptional results, whether you’re tackling a small DIY project or a large-scale restoration.

With our expertise and commitment to excellence, you can trust Rhino Wood Repair to provide you with the knowledge and tools you need to tackle any wood repair project with confidence. Visit our website or contact us today to learn more about our innovative wood repair solutions. Best products for people wondering can I stain an old fence?

by Robin Pixner | May 14, 2024 | News

If you’re a proud owner of a beautiful wooden deck, you know how important it is to protect it from the harsh elements. Deck stains are a popular choice for enhancing the natural beauty of wood while providing a protective barrier against moisture, UV rays, and other environmental factors. However, not all deck stains are created equal, and their effectiveness in protecting wood can vary greatly. In this comprehensive guide, we’ll explore the role of deck stains in wood protection and what you need to know to ensure your deck remains in pristine condition for years to come.

Understanding Deck Stains

What is Deck Stain?

Deck stains are specialized coatings designed to penetrate deep into the wood surface, providing both color and protection. These stains can range from semi-transparent to solid colors, allowing you to achieve the desired look while still showcasing the natural grain of the wood.

Types of Deck Stains

There are several types of deck stains available on the market, each with its own advantages and drawbacks:

- Oil-based stains: Provide superior penetration and water repellency but can be more difficult to apply and maintain.

- Water-based stains: Easier to apply and clean up, but may not offer the same level of protection as oil-based stains.

- Semi-transparent stains: Allow the natural wood grain to show through while providing some UV protection.

- Solid stains: Offer a more opaque finish and better UV protection but can obscure the wood’s natural beauty.

Deck Stain Protect Wood?

While deck stains can provide some level of protection, their effectiveness depends on several factors:

- Wood condition: Properly prepping and maintaining the wood surface is crucial for optimal stain performance.

- Application techniques: Following the manufacturer’s instructions and applying the stain correctly can significantly impact its longevity and protective properties.

- Environmental conditions: Extreme temperatures, moisture levels, and UV exposure can affect the stain’s durability over time.

- Maintenance: Regular cleaning and reapplication as recommended by the manufacturer are essential for maintaining the stain’s protective qualities.

Enhancing Deck Stain Protection

While deck stains offer valuable protection, there are additional measures you can take to further enhance your deck’s longevity:

- Use a wood preservative: Applying a wood preservative before staining can help protect against rot, decay, and insect damage.

- Incorporate wood repair products: Products like those from Rhino Wood Repair can effectively address weakened wood and enhance the durability and longevity of coatings like paint and stain.

- Maintain proper drainage: Ensure your deck has adequate drainage to prevent water pooling, which can lead to rot and premature stain failure.

- Regularly clean and inspect: Routinely clean and inspect your deck for signs of wear or damage, addressing any issues promptly.

Why Choose Rhino Wood Repair Products for Your Deck Stain Project?

Rhino Wood Repair products not only effectively address weakened wood but also enhance the durability and longevity of coatings like paint and stain. By incorporating Rhino Wood Repair products into your project, you get the best quality results!

FAQs about Deck Stains and Wood Protection

How often should I re-stain my deck?

The frequency of re-staining depends on various factors, including the type of stain used, exposure to sunlight and weather, and the condition of the wood. Most manufacturers recommend re-staining every 1-3 years for optimal protection.

Can I apply deck stain over an old, weathered surface?

While it is possible to apply deck stain over an old, weathered surface, proper surface preparation is crucial. The old stain or finish must be removed, and the wood must be cleaned and sanded to ensure proper adhesion and penetration of the new stain.

Will deck stain protect against mold and mildew?

Some deck stains contain additives that can help prevent mold and mildew growth, but their effectiveness can be limited in damp or shaded areas. Proper ventilation, cleaning, and maintaining a dry surface are essential for preventing mold and mildew growth.

Can I use deck stain on other outdoor wood surfaces?

Yes, many deck stains are suitable for use on other outdoor wood surfaces, such as fences, pergolas, and outdoor furniture. However, it’s always best to check the manufacturer’s recommendations for specific applications.

Top Tips for Protecting Your Deck with Stain:

- Choose a high-quality, reputable deck stain suitable for your climate and exposure conditions.

- Properly prepare the wood surface by cleaning, sanding, and addressing any necessary repairs.

- Follow the manufacturer’s instructions carefully for proper application and coverage rates.

- Consider incorporating wood repair products like those from Rhino Wood Repair for enhanced protection and longevity.

- Maintain your deck by regularly cleaning, inspecting, and re-staining as needed.

About the Author

This comprehensive guide on deck stain protection was brought to you by Rhino Wood Repair, a company dedicated to providing top-quality wood repair solutions. Our founder and chemist, Robin Pixner, has years of experience in the industry and a passion for helping homeowners and professionals alike achieve flawless woodwork.

At Rhino Wood Repair, we understand the importance of preserving the beauty and longevity of wood surfaces. Our products are carefully formulated to ensure exceptional results, whether you’re tackling a small DIY project or a large-scale restoration.

With our expertise and commitment to excellence, you can trust Rhino Wood Repair to provide you with the knowledge and tools you need to tackle any wood repair project with confidence. Visit our website or contact us today to learn more about our innovative wood repair solutions. See the best products for deck stain here.

by Robin Pixner | May 11, 2024 | News

Epoxy coatings have become a popular choice for protecting and enhancing wood surfaces, thanks to their durability, seamless finish, and resistance to moisture and chemicals. However, as with any DIY project, several potential pitfalls can occur if the application process is not executed correctly. In this comprehensive guide, we’ll explore what can go wrong when epoxy coating over wood and how to prevent these issues for a flawless finish.

Common Epoxy Coating Issues

Fisheyes and Craters

Fisheyes and craters are small, crater-like imperfections that can appear on the surface of the epoxy coating. These defects are often caused by contamination or improper surface preparation, which prevents the epoxy from adhering correctly.

Cloudy or Hazy Finish

A cloudy or hazy appearance in the epoxy coating can result from various factors, including improper mixing, insufficient hardener, or exposure to moisture during the curing process.

Soft or Sticky Areas

If the epoxy coating remains soft or sticky after the recommended curing time, it could be due to incorrect mixing ratios, insufficient hardener, or improper application techniques.

Peeling or Delamination

Peeling or delamination occurs when the epoxy coating separates from the wood surface. This issue is typically caused by inadequate surface preparation, contamination, or incompatibility between the epoxy and the wood substrate.

Preventing Epoxy Coating Issues

Surface Preparation

Proper surface preparation is crucial for a successful epoxy coating application. Follow these steps:

- Clean the wood surface thoroughly, removing any dirt, grease, or contaminants.

- Sand the surface to create a roughened texture for better adhesion.

- Remove all dust and debris from the sanding process.

Mixing and Application

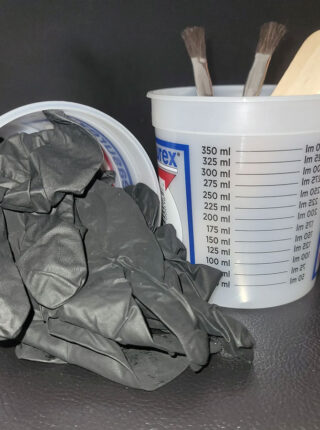

Carefully follow the manufacturer’s instructions for mixing and applying the epoxy coating:

- Mix the epoxy resin and hardener in the correct ratios, using a clean container and mixing stick.

- Ensure thorough mixing to avoid incomplete curing or soft spots.

- Apply the epoxy coating in thin, even layers, following the recommended coverage rates and application techniques.

Environmental Conditions

Pay close attention to the environmental conditions during application and curing:

- Maintain the recommended temperature range for proper curing.

- Ensure adequate ventilation to prevent moisture buildup or contamination.

- Avoid drafts or excessive air movement, which can introduce dust or debris.

FAQs about Epoxy Coating Over Wood

Can I apply epoxy over stained or painted wood?

While it is possible to apply epoxy over stained or painted wood, proper surface preparation is crucial. The existing finish must be thoroughly deglossed or sanded to ensure proper adhesion.

How long does epoxy take to cure?

Curing times can vary depending on the specific epoxy product and environmental conditions. Typically, epoxy coatings can take anywhere from 24 to 72 hours to fully cure.

Can I recoat or touch up an existing epoxy coating?

Yes, it is possible to recoat or touch up an existing epoxy coating, but the surface must be properly prepared by sanding and cleaning to ensure proper adhesion.

Is epoxy coating over wood food-safe?

Not all epoxy coatings are food-safe. If you plan to use the coated surface for food preparation or consumption, ensure you choose a specifically formulated food-safe epoxy coating.

Top Tips for Successful Epoxy Coating Over Wood:

- Thoroughly clean and prepare the wood surface for optimal adhesion.

- Follow the manufacturer’s mixing and application instructions precisely.

- Maintain the recommended temperature and ventilation conditions during application and curing.

- Apply the epoxy coating in thin, even layers for a smooth, consistent finish.

- Allow sufficient curing time before subjecting the surface to heavy use or wear.

About the Author

This comprehensive guide on potential issues with epoxy coating over wood was brought to you by Rhino Wood Repair, a company dedicated to providing top-quality wood repair solutions. Our founder and chemist, Robin Pixner, has years of experience in the industry and a passion for helping homeowners and professionals alike achieve flawless woodwork.

At Rhino Wood Repair, we understand the importance of preserving the beauty and longevity of wood surfaces. Our products are carefully formulated to ensure exceptional results, whether you’re tackling a small DIY project or a large-scale restoration.

With our expertise and commitment to excellence, you can trust Rhino Wood Repair to provide you with the knowledge and tools you need to tackle any wood repair project with confidence. Visit our website or contact us today to learn more about our innovative wood repair solutions. See our wood repair products here.

by Robin Pixner | May 8, 2024 | blogs, News

Are you dealing with unsightly holes, cracks, or dents in your wood surfaces? Don’t let them ruin the beauty of your woodwork! Applying wood filler is an easy and cost-effective solution to restore the smooth and flawless appearance of your wooden furniture, floors, or trim. In this comprehensive guide, we’ll walk you through the process of choosing the right wood filler and applying it like a pro.

Understanding Wood Filler

What is Wood Filler?

Wood filler is a putty-like compound designed to fill gaps, holes, and imperfections in wood surfaces. It’s typically made from a combination of wood fibers, resins, and other additives, allowing it to blend seamlessly with the surrounding wood once dry.

Types of Wood Filler

Not all wood fillers are created equal. Here are some common types:

- Water-based: Easy to clean up and environmentally friendly.

- Solvent-based: Stronger and more durable, but with a stronger odor.

- Epoxy-based: Ideal for larger holes and cracks, as it dries rock-hard.

- Stainable: Designed to accept stains and finishes for a seamless match.

Preparing the Surface

Proper surface preparation is crucial for successful wood filler application. Here are the steps to follow:

- Clean the area: Remove any loose debris, dust, or dirt from the surface using a vacuum or a clean cloth.

- Sand the area: Lightly sand the surface around the imperfection to create a smooth transition and help the wood filler adhere better.

- Remove any debris: Vacuum or wipe away any remaining dust or debris from the sanding.

Applying the Wood Filler

Now that your surface is prepped, it’s time to apply the wood filler. Follow these steps for a flawless finish:

- Read the manufacturer’s instructions carefully for any specific application guidelines.

- Scoop out a small amount of wood filler onto a putty knife or a piece of cardboard.

- Press the wood filler firmly into the imperfection, ensuring it fills the gap completely.

- Use a putty knife or your finger to smooth the wood filler flush with the surrounding surface.

- Allow the wood filler to dry completely according to the manufacturer’s instructions.

Sanding and Finishing

Once the wood filler has fully dried, it’s time to sand and finish the surface:

- Lightly sand the area with fine-grit sandpaper (220-grit or higher) to create a smooth, even surface.

- Wipe away any remaining dust or debris.

- If desired, apply a stain or finish to the area to match the surrounding wood.

FAQs about Wood Filler

Can I use wood filler on exterior surfaces?

While some wood fillers are designed for exterior use, it’s generally recommended to use an exterior-grade wood filler or epoxy for outdoor projects to ensure long-lasting durability.

How long does wood filler take to dry?

Drying times can vary depending on the type of wood filler, humidity, and temperature conditions. Water-based wood fillers typically dry within 1-2 hours, while solvent-based and epoxy fillers may take several hours or overnight to fully cure.

Can I stain over wood filler?

Yes, many wood fillers are designed to accept stains and finishes. However, it’s essential to choose a stainable wood filler if you plan on staining the area to ensure a seamless match.

How do I clean up excess wood filler?

Excess wood filler can be removed before it dries using a damp cloth or mineral spirits (for solvent-based fillers). Once dried, sanding is the best way to remove any excess or smooth out the surface.

Top Tips for Applying Wood Filler:

- Work in multiple thin layers for deeper imperfections.

- Use a putty knife or your finger to smooth the wood filler flush with the surrounding surface.

- Allow the wood filler to dry completely before sanding or finishing.

- Sand in the direction of the wood grain for a seamless finish.

- Always follow the manufacturer’s instructions for best results.

About the Author

This comprehensive guide on applying wood filler like a pro was brought to you by Rhino Wood Repair, a company dedicated to providing top-quality wood repair solutions. Our founder and chemist, Robin Pixner, has years of experience in the industry and a passion for helping homeowners and professionals alike achieve flawless woodwork.

At Rhino Wood Repair, we understand the importance of preserving the beauty and longevity of wood surfaces. Our products are carefully formulated to ensure exceptional results, whether you’re tackling a small DIY project or a large-scale restoration.

With our expertise and commitment to excellence, you can trust Rhino Wood Repair to provide you with the knowledge and tools you need to tackle any wood repair project with confidence. Visit our website or contact us today to learn more about our innovative wood repair solutions. See our wood rot repair treatments here.

by Robin Pixner | Jun 7, 2024 | News

Wood is a remarkably durable and versatile material, widely used in construction, furniture, and various other applications. However, despite its strength, wood is susceptible to rot and decay under certain conditions. Knowing how long it takes for wood to rot can help you take preventive measures and address any issues promptly before they escalate. In this comprehensive guide, we’ll explore the factors that influence wood rot and provide insights into the typical timeline for this process to occur.

Factors Affecting Wood Rot

Moisture Content

Moisture is the primary catalyst for wood rot. Wood with a moisture content above 20% creates an ideal environment for fungi and bacteria to thrive, leading to the breakdown of the wood’s cellular structure. Sources of moisture can include excessive humidity, leaks, poor ventilation, or direct exposure to water.

Wood Type

Different wood species have varying levels of natural resistance to rot. Hardwoods like oak and teak tend to be more resistant than softwoods like pine or cedar. The density and chemical composition of the wood play a significant role in its durability against rot and decay.

Environmental Conditions

Temperature, humidity, and exposure to sunlight can all impact the rate at which wood rots. Generally, warm and humid environments with limited air circulation provide ideal conditions for fungi and bacteria to thrive, accelerating the rot process.

Typical Timelines for Wood Rot

While the exact timeline can vary depending on the specific conditions, here are some general guidelines for how long it takes for wood to rot:

Untreated Wood in Ideal Conditions

In optimal conditions for rot, such as high moisture levels, warm temperatures, and poor ventilation, untreated wood can begin to show signs of decay within a few months. Significant structural damage can occur within 1-2 years if the conditions persist.

Treated or Naturally Rot-Resistant Wood

Wood that has been treated with preservatives or naturally rot-resistant species like cedar or redwood can take significantly longer to rot. Under ideal conditions, treated wood may not show signs of decay for several years, while naturally rot-resistant wood can last up to a decade or more before succumbing to rot.

HWell-Maintained and Protected Wood